Parmigiano-Reggiano Cheese Factory, Parma

Posted on May 01, 2012 under Archives, Italy | 3 CommentsWhile in Parma last month, I met Andrea Aiolfi, head of Food Valley Gourmet Tours, who was nice enough to take me on a day long tour of a few of the many food factories in Parma. Our first stop was a Parmigiano-Reggiano Cheese Factory.

In making Parmigiano- Reggiano , cheesemakers in Parma follow a carefully controlled process that sets requirements on everything from feed for the dairy cattle to the aging of the cheese .

Before a cheese can be branded with the trademark, Parmigiano- Reggiano, the guarantee of quality, it must pass several inspections by experts with the Parmigiano- Reggiano Consortium, as well as the many observations made by workers at the factory as they handle the cheese during the brining, drying and aging.

Andrea and his guides pick up travelers at their hotel and drive them to each factory. We started with the king of cheeses, Parmigiano-Reggiano, and had to suit up before entering the factory. We put on plastic coats, hats and covering for our shoes.

By Italian law, Parmigiano- Reggiano is produced only in a defined territory or zone in northern Italy, mostly in the Emilia Romagna region. The territory comprises the communes of Parma, Reggio Emilia and Modena, the part of Bologna on the left bank of the Reno River and the part of Mantua (in the Lombardy region) that is on the right bank of the Po River.

About 80 percent of the milk that yields Parmigiano- Reggiano comes from 200,000 Frisona Italiana – Italian Friesian – cows, with 1 percent from a breed called Rossa Reggiana, and the rest mostly from Brown Swiss.

The production of milk also is controlled and inspected by the cheese consortium. The cows are fed hay and grass.

Their milk is delivered twice a day to the cheese plant. An evening’s milk is poured into large stainless-steel pans and skimmed the next morning. Then the morning’s whole milk from the dairies is added to the skim milk, and both are piped into the large copper cauldrons. With the addition of rennet, a natural ingredient from calves, the milk is heated slowly until it reaches the proper temperature to form curds and maintain the correct softness. Nothing else is added.

As the curds separate from the liquid, they are gathered into a mass, and a large cloth woven of linen and cotton is slipped under and around the mass of curds. The cloth is tied at two ends over a wooden pole that is placed across the top of the cauldron.

The cheese drains and each mass of cheese is divided with a special knife, and one of the halves is placed in a second cloth. Both halves are retied and suspended on the wooden pole across the copper pot. Two wheels of Parmigiano- Reggiano are the daily yield from each cauldron. The remaining curd is then gathered and can immediately be sold as fresh Ricotta.

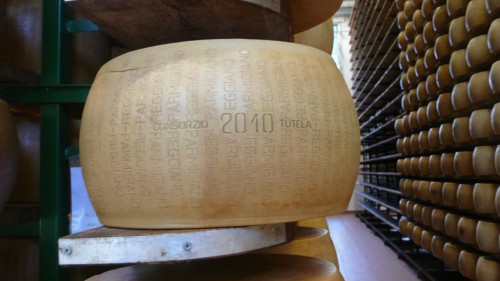

This very young cheese is placed in molds lined with a matrix that presses the words “Parmigiano- Reggiano ” into what will be the rind around the girth of the wheel of cheese . The date and the dairy number are also pressed into the cheese.

The cheeses stay in the molds two or three days before they are removed and placed in a brine of pure water and sea salt for three to four weeks.

After the brine bath, the cheeses go into storage and are placed on wooden shelves that reach to the ceiling of the aging room, where they are turned many times to prevent any spoilage to the cheese and damage to the wood. On these shelves, sometimes holding 200,000 cheeses , the Parmigiano-Regiano receives most of its inspections, such as thumping for solidity, visual observations and a coring sample.

Most cheese factories have a selling room where visitors can buy ricotta, parmigiano-reggiano and other cheeses. The parmigiano-reggiano can be vacuum-sealed in heavy plastic enabling tourists to transport it and enjoy it at home. Prices usually range from $12 to $14 per kilo. We sampled a nice bunch of cheeses all aged from eighteen months to three years.

To be labeled “export quality,” each cheese must be aged for a minimum of 18 months. Here are the kilos I purchased which I am now enjoying at home.

The parmigiano-reggiano cheese factory was just the first stop on my food tour with Andrea. I highly recommend booking a food tour with Food Valley Gourmet Tours if you are traveling to Parma, reservations can be made on their website at www.foodvalleytravel.com.

May 12th, 2012 at 1:35 am

Hello,

I would like to visit a parmesan factory in Parma and I can`t find any information about tours arrangements. Could you please give me any contact to find out more about it?

Thank you,

Yana

May 14th, 2012 at 4:00 pm

You can go to the website http://www.foodvalleytravel.com and email them (Andrea) to schedule a tour in Parma.

February 25th, 2013 at 8:03 am

I love to see the parmesan cheese production any time, it is an art form! and than you sharing the pictures of your experience.